Embracing Change: How Moving Forward Can Lead You Back Home

“Never go back, always look to move forward.”

This mantra was something my father stood by and would reiterate whenever...

While most manufacturing plants have a process historian they often suffer from an inability to use the data for decision making. With such a large data repository, the data can be used for regulatory reports, OEE, Track & Trace, inventory management, utility billing, batch report data, alarms and events, production performance improvement, predictive maintenance, to name a few. ACE can help you put your data to use today. Our MES, OT and data specialists can connect your database to all related systems from your ERP to the plant floor to empower your team to make more informed decisions, and alleviating pressure associated with manual reporting. ACE will securely integrate the data with business management systems and leverage the data through the MES to positively impact your bottom line.

The first step on the path towards digital transformation is unifying data into a single repository.

Reporting is required to demonstrate regulatory compliance with various agencies such as FDA and EPA and is critical for operating your manufacturing plant. You need to collect and store data and use it to create reporting now and in the future. ACE will help to query data from various sources, make the necessary calculations, and generate the report meeting the regulatory requirements. The report can be automatically e-mailed or stored in a specific file location, or generated on demand, as determined in collaboration with your team. Together, we identify retention policies and store the data for long-term access and ease of retrieval. ACE has the expertise and experience to design and implement a reporting system utilizing the best tools available.

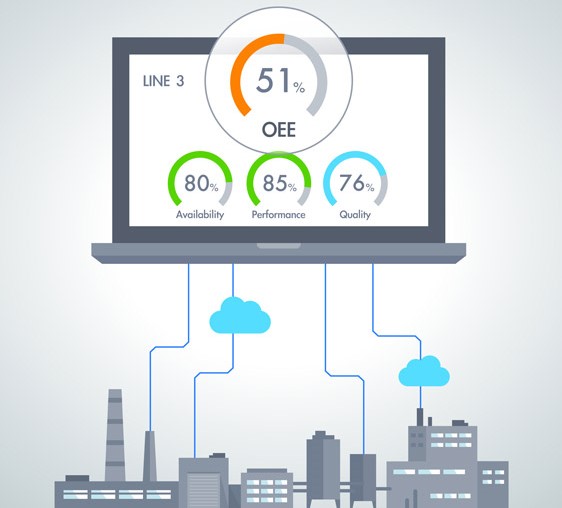

Projects that implement process historians often stop at the data collection stage. You are not getting the full power of the Historian if you are not contextualizing the data to provide actionable real-time information to process stakeholders. ACE will implement a full MES/MOM system, configuring it to provide OEE metrics, KPI’s, dashboards, events, and analytics in the form each role in your organization needs, from the plant floor to the C-suite.

Historians that collect data from OT systems and do not interface with higher level systems such as ERP, inventory control and production scheduling are under-utilized and represent a missed opportunity in today’s competitive market. Through data interfaces, ACE can help you leverage your historian data with your other management systems. This includes triggering work orders in your CMMS based on process data, incorporating LIMs quality information into a batch record, and passing inventory data to the ERP. Since ACE has extensive OT experience at both the plant and MES/MOM levels, we are uniquely suited to help you identify and implement these connections for better data utilization.

There are numerous decisions to make as you network your systems’ data into a single database as you start your path towards digital transformation. If you do not have recent experience with deploying a historian, you may not be aware of the latest tools and standards for networking and historian implementation. Keeping up to date with latest tools and approaches is difficult, and ACE can help, especially when collaborating with multiple stakeholders including IT, OT, and senior management. ACE augments the experience of your team with our seasoned OT staff to make sure you are using the right software, hardware, and networking tools to create a repository that meets your availability, integrity, and confidentiality requirements.

Cyber security is an important concern for any site with a process historian. The OPC interface to your process control system provides a standard for interfacing to multiple vendor systems while simplifying malicious manipulation of these same control systems. ACE will help control access to your systems through a comprehensive Cybersecurity approach, incorporating defense in depth strategies. From modifying interfaces to be setup for read-only access, implementing access control rules and configuring firewalls, ACE works to make your system safe. These strategies require expertise with process control, IT and OT systems knowledge. This is where ACE excels. We have experienced individuals to work with your organization to implement the right solution.

“Never go back, always look to move forward.”

This mantra was something my father stood by and would reiterate whenever...

Overall Equipment Effectiveness or OEE, is a best practice method of measuring the manufacturing productivity of your...

Today, there are many internal and external challenges manufacturers must navigate to efficiently manage orders such as...